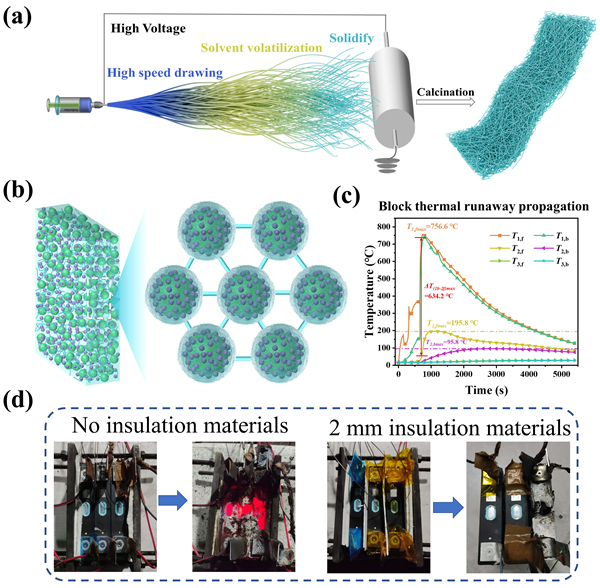

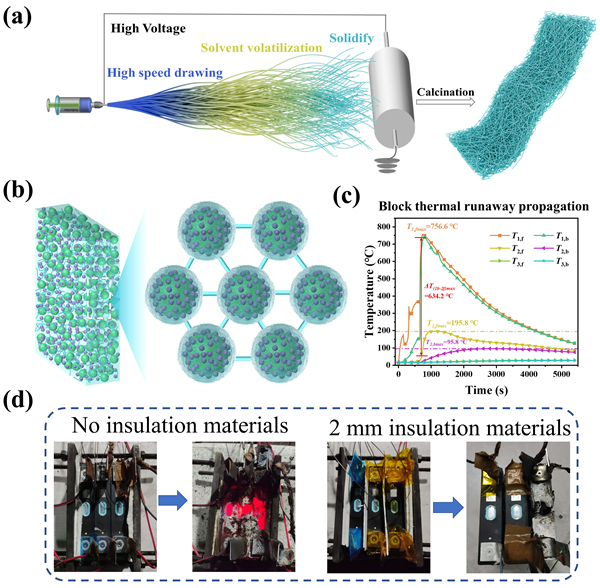

Thermal runaway propagation (TRP) remains a major challenge for lithium-ion batteries (LIBs) safety, with heat conduction being the primary transfer mode in battery modules. To mitigate TRP, thermal insulation materials are commonly integrated into battery modules to block heat transfer from a failing battery. However, under abuse conditions, rapid gas generation causes battery expansion, leading to an average pressure of 0.3 MPa and localized spikes of up to 1 MPa, compromising conventional insulation materials. Specifically, flexible materials like fibrous aerogels offer excellent insulation but lack compressive strength (<10 kPa), while rigid materials provide mechanical stability but inadequate thermal insulation. Therefore, developing an insulation material that combines both high compressive strength and excellent thermal insulation performance is crucial for enhancing LIB module safety.

Prof. Qingsong Wang from SKLFS has developed an ultra-pressure-resistant composite insulation material with a compressive strength of 1.45 MPa. TRP tests demonstrate that a 2-mm-thick layer of this composite material effectively prevents TRP within the battery module containing 58 Ah NCM batteries, achieving a maximum temperature difference of 634.2 °C. These findings have been published in Energy Storage Materials (76 (2025) 104148).

Schematics of insulation material fabrication, structure, and performance in battery modules. (a)Schematic of the electrospinning process. (b)Schematic of the internal structure of the insulation material. (c)Temperature profile of the battery module with a 2 mm insulation layer. (d)Photographs of the battery module before and after testing with and without insulation material.