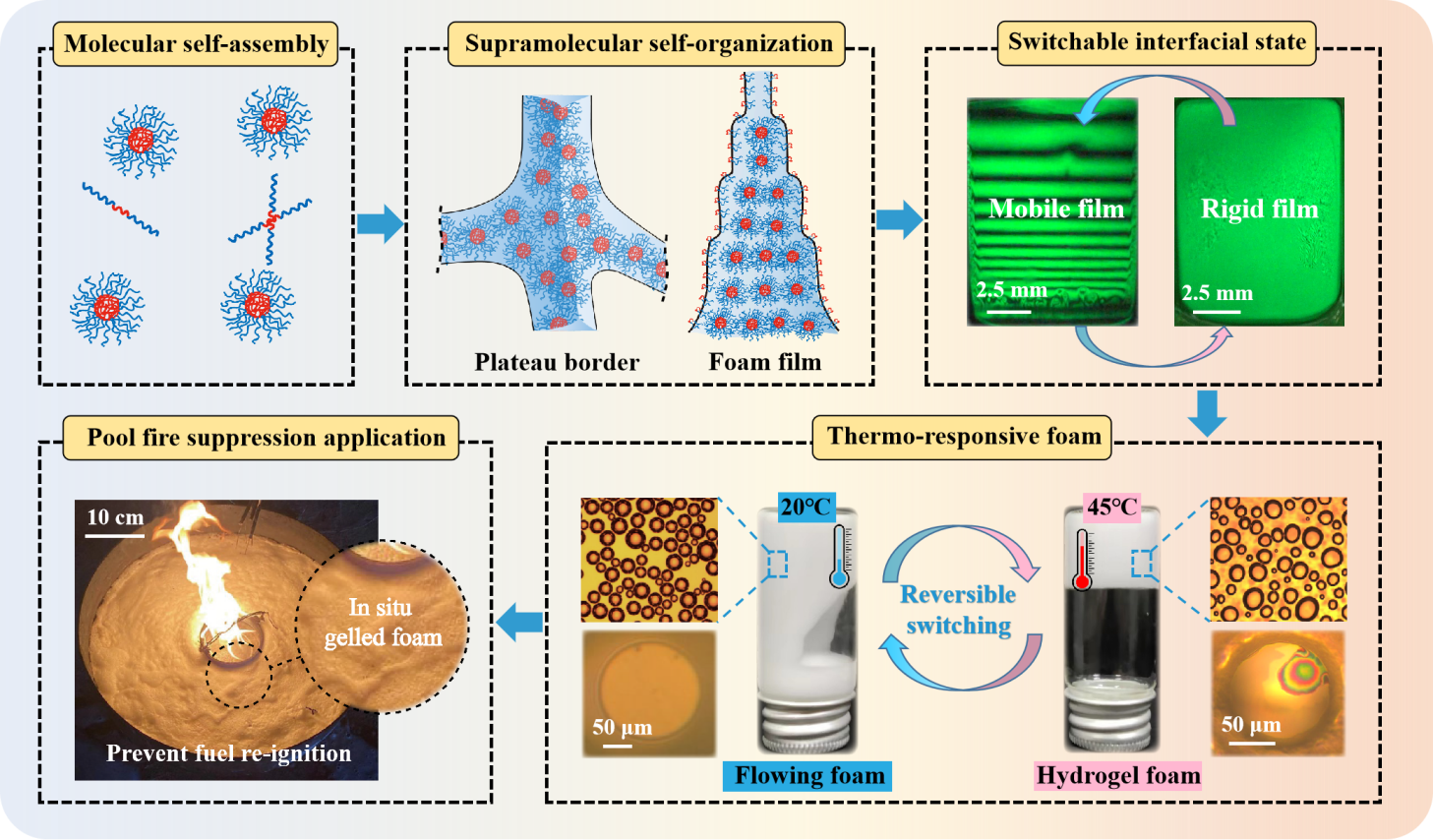

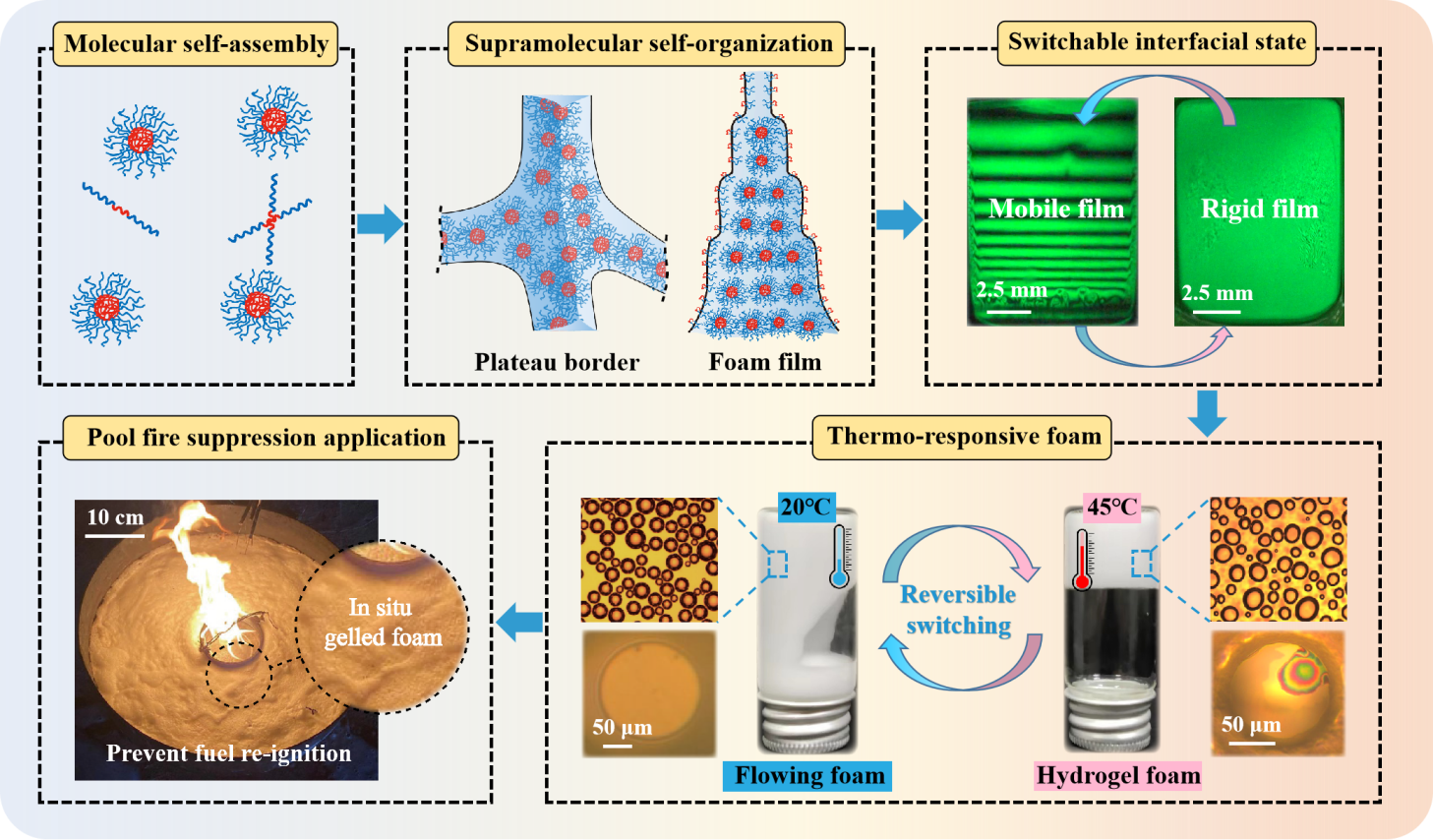

Aqueous film-forming foam (AFFF) has been considered the gold standard for pool fire suppression. It was the fluorocarbon surfactants contained in AFFF that were essential to enhance the pool fire suppression performance. However, the perfluorooctyl-based surfactant have been shown to be bio-persistent, bioaccumulative, and toxic because of the extremely high stability of fluorine-carbon bonds in hydrophobic tails. The development of novel fluorine-free fire-fighting foams to replace fluorinated AFFF is crucial both for improving fire suppression performance and environmental protection. Professor Shouxiang Lu and Dr. Xiaoyang Yu, from State Key Laboratory of Fire Science, have developed a thermo-responsive fluorine-free foam with designed triblock PEO–PPO–PEO copolymers, contributing to the development of smart fire-suppression materials. By controlling the molecular self-assembly, the liquid foam exhibited a switchable interfacial state for reversible switching between flowing and hydrogel foam under different temperatures. Based on the mechanism, the burnback performance exhibited by thermo-responsive copolymer foams is 3 times better than that for classical fluorine-free foams and almost 1.5 times higher than that for commercial AFFF. The associated work was published in the SmartMat (the top journal of material science with an impact factor of 15.3) and has been recognized as a top cited article in this journal.

Note: The non-ionic triblock PEO–PPO–PEO copolymers, as the building blocks for thermo-responsive foams, could create interfacial and bulk ensembles that could be reversibly switched between mobile and rigid states at gas–liquid interfaces, in response to changes in bulk concentration and fuel temperature. The active switching of the two interfacial states led to the significant enhancement of the foam stability, especially under the dual defoaming effects of heat and oil, and thermo-responsive fluorine-free foam had stronger stability than fluorinated foam.