Because of the lack of sustainable global petrochemical energy supply and more serious environmental pollutions such as emissions from automobiles, people have now come to know the importance of exploration on new clean energy. In order to ensure sustainable developments, steady storage and transportation of the energy, ideal energy storage equipment is essential. Owing to the high voltage, high specific energy, low self-discharge rate, long cycle life and environment friendly, lithium ion batteries have become the leading products in the field of consuming and industrial electronics. However, the fire and explosion incidents of lithium ion batteries because oftheir poor thermal stability have been reported recently. Thus, the safety of lithium battery is still one of the major issues which limit its industrial application in the area of electric vehicles or hybrid electronic vehicles.

In recent years, the industrial fire group, led by Professor Sun Jinhua, is working on the safety of lithium ion battery to reveal the in-depth mechanisms of battery fire and explosion. Our group has collaborated with the lithium ion battery laboratory of USTC to study the electrochemical properties and thermal stability of the lithium ion battery electrolyte, the cathode and anode materials under different state of charge condition and the electrolyte-electrode coexisting systems by thermal-electrical coupling analysis.

The dynamics, thermodynamics and electrochemical properties of different lithium ion battery materials and their coexisting systems have been investigated, the mechanisms of battery fire and explosion have been investigated, and the effective measures to enhance the safety of lithium ion battery has been proposed. Part of the studies has been published on high-quality journals, such asJournal of Power Sources, Journal of Hazardous Materials, andJournal of the Electrochemical Society etc. Meanwhile, some patents have also been filed. Up to now, about 30 professional papers have been published and 22 have been indexed by SCI.

The study showed that the strong Louis acid effect of PF5 in the commercial electrolyte is the main factor that reduces the thermal stability of lithium ion battery. When the electrolyte coexists with the cathode or anode materials, the thermal stability of the system will be reduced to a lower level. The thermal stability of the cathode material LixCoO2 and its coexisting system with electrolyte both decrease with the charge level increased. The effect of numbers of lithium ions intercalated into the anode material on the thermal stability of the anode and its coexisting system with electrolyte is less. By the comprehensive analysis of various materials of lithium ion batteries in different charge levels, we found the explosion of lithium ion battery is essentially a phenomenon of swallowtail catastrophe.

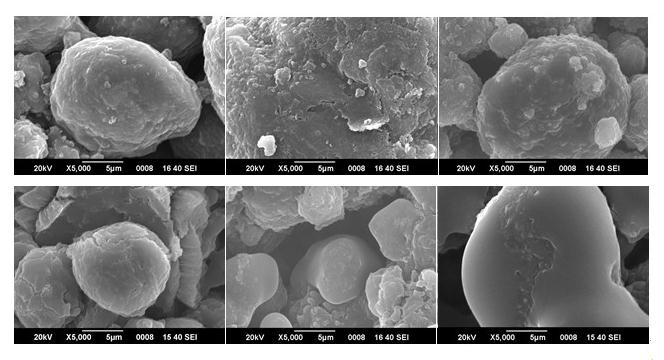

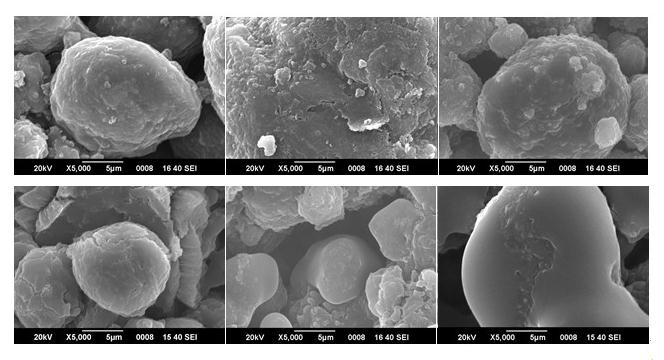

Furthermore, our group has studied the battery electrolyte materials with high safety requirements. Recently, we proposed IPPP and CDP as flame retardant for the lithium ion battery, which can decrease the inflammability evidently based on the guaranteed electrochemical performance of the battery. Except that, we analyzed the performance of the electrolyte based on a LiBOB salt, lactone solvent and sulfite additive. By using this new electrolyte, the electrical conductivity and the compatibility of electrode-electrolyte are both enhanced. In particular, a smooth and effective SEI film is formed on the anode surface, which reduces the interface resistance of the battery (Fig. 1). Moreover, owing to the effect of Lewis acid is decreased significantly of this electrolyte, the thermal stability of the electrode-electrolyte system is confirmed (Fig. 2), which improve the electrochemical performance and the thermal stability of the lithium ion battery effectively.

|

Fig. 1. After the addition of different sulfite into the electrolyte, the SEM images of anode material MCMB after cycle. (Cited from Ping et al. / Journal of Power Sources 196 (2011) 776–783) |

|

Fig. 2. The heat flow curves of the common electrolyte and the LiBOB/GBL electrolyte join after the addition of different sulfite. (Cited from Ping et al. / Journal of Power Sources 196 (2011) 776–783) |